Today, an old friend from Egypt visited our factory. He owns many plastic factories in Egypt and has visited China many times. He plans to purchase PET machines in China and is very interested in our machines. So, what kind of PET machines are they that he is so interested in?

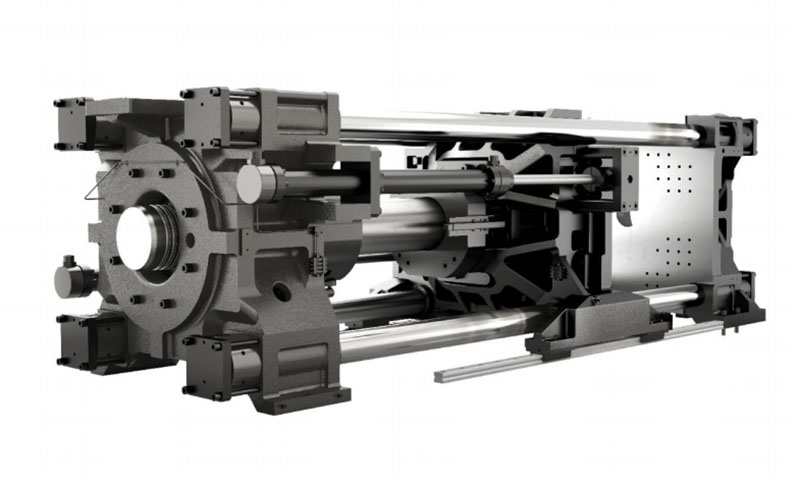

First, he noticed our unique twin-screw structure. Of course, other factories also have twin-screw structures. Why is our company's twin-screw structure so special?

Unique twin-screw structure: Lisong injection molding machine features two screws, an upper screw dedicated to material storage and plasticization, and a lower screw dedicated to injection and pressure maintaining. The twin-screw structure boasts the capability of simultaneous injection and pressure maintaining while storing material, effectively ensuring uniform plasticization and product perfection, and significantly reducing cycle time. The PET-specific twin-screw structure guarantees rapid and precise injection, while the low-speed material storage and high-efficiency plasticization effectively control the AA value. The screw incorporates a brand-new infrared heating coil, significantly reducing energy consumption and ensuring faster and more precise heating.

Proprietary patented clamping system: The maintenance-free clamping system ensures long-term stable production, with no lubricant pollution in the clamping area, effectively protecting the food safety of the products. It features a patented direct pressure clamping structure, unlike the inverting machine, where the toggle arms are distributed at four corners. The injection molding machine from Lisong directly clamps at the center, providing greater clamping force and higher precision. With direct pressure clamping, the mold plate deformation is minimal, and the machine parallelism follows the mold, ensuring consistency of each cavity product.

After our Egyptian friends visited our PET machine, they still had issues with our mold clamping system.

For expensive molds, will the injection molding machine burn out the mold during mold clamping.

Therefore, our Lisong system boasts low-pressure mold protection, featuring ultra-sensitive low-pressure mold protection (with a clamping force only one-thirtieth of the locking force), providing effective protection for the mold.

After visiting our PET machines, our Egyptian friends were full of praise for them. Amidst the impact of Chinese manufacturing, Chinese machines, including those from Lisong, are advancing towards the world

Friends from Pakistan

A Pakistani brother came to visit our factory, and I, along with my good partner, received the client from Pakistan.

I took them from the factory producing robotic arms for injection molding machines, to the chiller factory, and then to our factory. Firstly, he marveled at the rapid pace of China's development, as well as the swift progress of China's machinery industry, including the injection molding machine sector.

When visiting Lisong's factory, the first thing he saw was the green logo of Lisong and the huge factory building. He also noticed the beautiful garden and impressive lobby of Lisong, but most importantly, he was impressed by the clean factory and the machines operating at high speed.

He stopped in front of a machine producing thin-walled food containers and looked at the unique structure of the Lisong thin-walled food container machine. He was very interested in our thin-walled food container machine.

What are the advantages of Nalisong thin-walled food containers?

The patented direct clamping structure, unlike the inverting machine, features toggle arms distributed at four corners. The injection molding machine from Lisong directly clamps at the center, achieving greater clamping force and higher precision. With direct clamping, the mold plate experiences minimal deformation, and the machine maintains parallelism with the mold, ensuring consistency in each cavity's product.

High-rigidity frame: High-rigidity design, tempering, and surface plastic spraying treatment. The enlarged feeding port allows for direct detachment and picking of products.

precise temperature control

Equipped with a standard infrared nano-heating coil, it features fast heating, excellent heat retention, and energy savings of over 30%. With closed-loop PID temperature control, it offers precise temperature regulation and superior process control stability.

The optimized screw with a large L/D ratio, low shear, and high mixing efficiency achieves good mixing and plasticizing efficiency.

Efficient plasticization drive

Precise and efficient servo technology ensures accurate injection movements.

Pakistani friends watched as high-quality products were taken out of the molds by robotic hands. The flawless products and high-speed machines are a testament to Lisong commitment to quality, as they reduce costs and enhance the performance and effectiveness of the machines.