In the dynamic world of PET injection molding, efficiency and precision are paramount. LISONG High-Speed Injection Molding Machines are at the forefront of this industry, offering cutting-edge technology tailored for PET preform and water bottle production. With a focus on speed, energy efficiency, and reliability, LISONG machines are redefining standards in high-speed molding.

Key Features and Parameters:

1.High-Speed Performance: LISONG machines achieve cycle times as low as 3.5 seconds, making them ideal for high-volume PET preform production.

2.Energy Efficiency: Equipped with advanced servo-driven systems, these machines reduce energy consumption by up to 25% compared to traditional models, aligning with global sustainability goals.

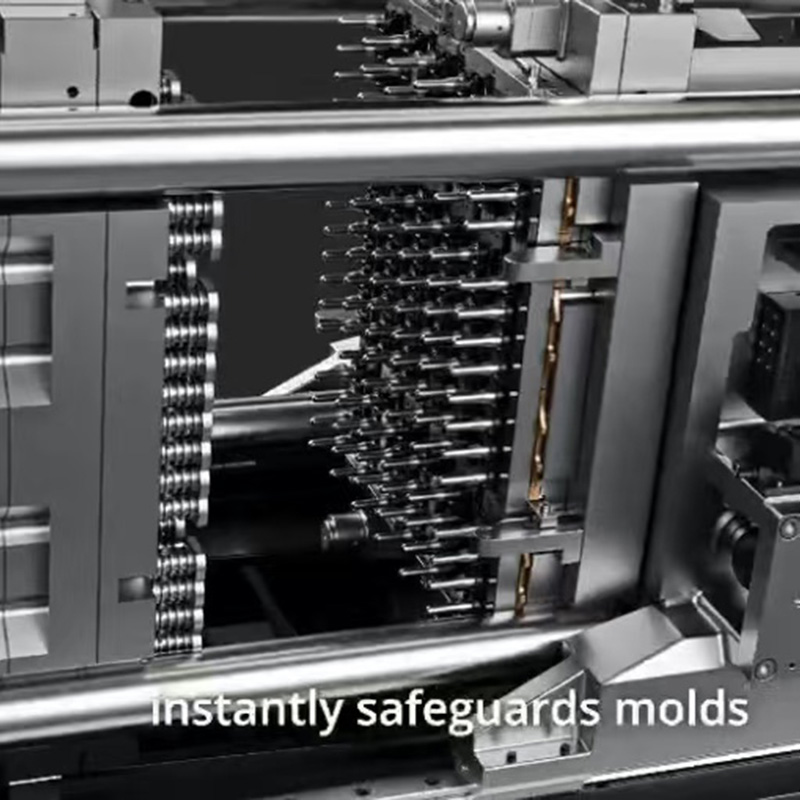

3.Precision Engineering: With a repeatability accuracy of ±0.1mm, Lisong ensures consistent quality in every mold, minimizing waste and maximizing output.

4.Smart Control: Integrated AI-driven energy management systems dynamically adjust power output based on production demands, further optimizing energy use.

5.Durability and Reliability: Built with robust components and featuring 7×24 monitoring, LISONG machines deliver uninterrupted performance, reducing downtime and maintenance costs.

Applications: LISONG High-Speed Injection Molding Machines are particularly suited for PET water bottle preforms, where speed and precision are critical. Their ability to handle high-volume production with minimal energy consumption makes them a preferred choice for manufacturers aiming to balance productivity and sustainability.

Conclusion: In an industry where every second and watt counts, LISONG High-Speed Injection Molding Machines stand out as a game-changer. By combining speed, precision, and energy efficiency, they empower manufacturers to meet the growing demands of PET preform production while reducing their environmental footprint. Choose LISONG for a smarter, faster, and greener future in injection molding.