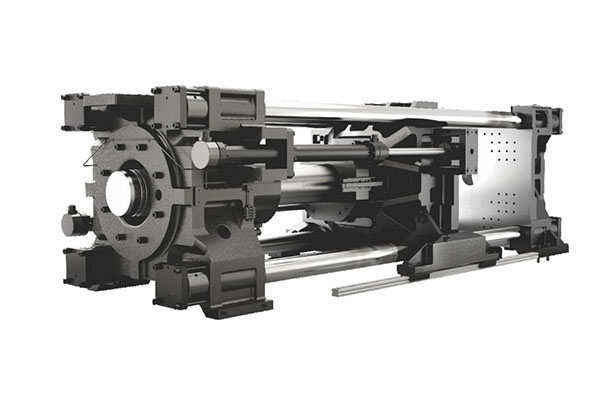

Direct pressure locking structure

The direct pressure locking structure of an injection molding machine is a locking method that provides locking force directly through a hydraulic cylinder. It consists of a template, a pull rod, an oil cylinder, and a mold adjustment mechanism, which can achieve the opening and closing action of the injection molding machine.

Advanced control panel

The control panel of an injection molding machine is the core of the interaction between the operator and the machine. It consists of multiple modules such as a display module, a key input area, manual operation keys, and function selection keys. It is used to control the entire injection molding process, monitor the running status in real time, and partially store data to assist in production management.

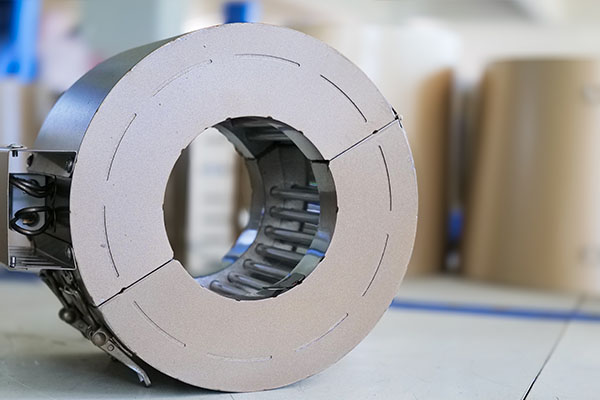

Infrared heating comprehensively reduces energy consumption losses

Infrared nano heating coil is an efficient and energy-saving heating device that generates heat energy through high resistance electric heating wires, and then converts the heat energy into far-infrared radiation through infrared radiation tubes to heat the material cylinder of the injection molding machine in a radiative manner.

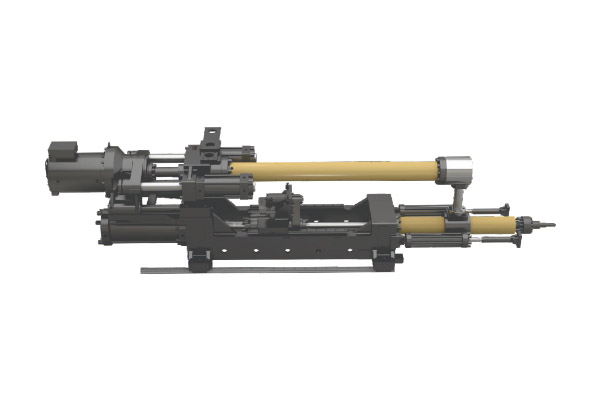

Independent Twin-Screw Injection System

The independent twin-screw injection system consists of a dedicated plasticizing screw and a separate injection screw. The plasticizing screw is responsible for the feeding, compression, melting, and venting of PET material, while the injection screw handles melt metering, accumulation, and the injection phase.

Servo drive control system

The injection molding machine servo driver is a key component that connects the injection molding machine and the servo motor. It is used to convert the pulse signal of the controller into a voltage or current signal that drives the servo motor, achieving precise control of the injection molding machine.

Maintenance-Free Mold Clamping System with Zero Oil Contamination in the Clamping Area

High Template Stability

Low-Pressure Mold Protection

PET-Specific Twin-Screw Design for Rapid and Precise Injection