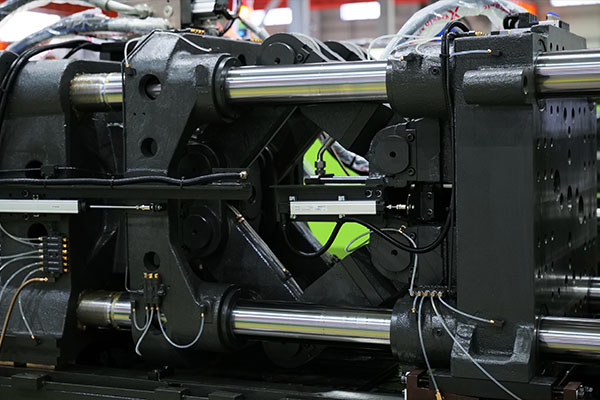

Clamping Structure

The direct-pressure clamping system of an injection molding machine is a method where the clamping force is directly provided by hydraulic cylinders. Composed of mold platens, tie bars, cylinders, and mold adjustment mechanisms, this system facilitates the mold opening and closing actions of the machine.

Advanced control panel

The control panel of an injection molding machine is the core of the interaction between the operator and the machine. It consists of multiple modules such as a display module, a key input area, manual operation keys, and function selection keys. It is used to control the entire injection molding process, monitor the running status in real time, and partially store data to assist in production management.

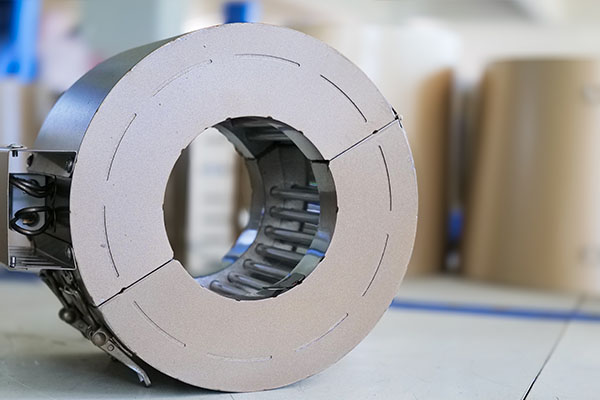

Infrared heating comprehensively reduces energy consumption losses

Infrared nano heating coil is an efficient and energy-saving heating device that generates heat energy through high resistance electric heating wires, and then converts the heat energy into far-infrared radiation through infrared radiation tubes to heat the material cylinder of the injection molding machine in a radiative manner.

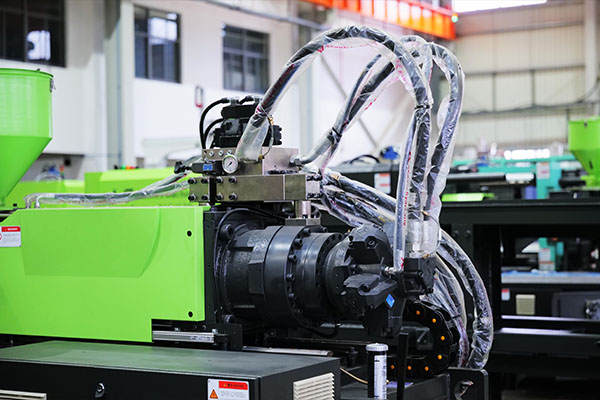

Hydraulic System

Sensitive and Powerful Drive for Energy Efficiency and High Performance: Utilizing a variable displacement pump for oil supply, the system achieves power matching between the hydraulic pump and actuators through load sensing, resulting in high efficiency and significant energy savings. Furthermore, the application of cartridge valve technology offers substantial flow capacity, rapid response, and reliable sealing performance. Additionally, the use of electro-hydraulic proportional directional valves enables combined control over the direction and speed of actuators, precisely meeting the flow requirements for various injection molding machine operating conditions.

Servo drive control system

The injection molding machine servo driver is a key component that connects the injection molding machine and the servo motor. It is used to convert the pulse signal of the controller into a voltage or current signal that drives the servo motor, achieving precise control of the injection molding machine.

Mold closure, with minimal deformation of the template, making it easier to form

responsive

Low probability of oil leakage