Years in the Industry: Witnessing Pain Points and a New Opportunity

As an editor with over a decade of experience in the injection molding machine industry, I have seen countless PET manufacturers plagued by excessive acetaldehyde levels, inadequate production capacity, and low efficiency. I have also witnessed many franchisees stuck in the dilemma of homogeneous competition because of poor product choices—until I came across this independent twin-screw injection system, which truly offers a breakthrough direction and new franchise opportunities in the PET injection molding space.

PET Injection Pain Points: Plagues for Manufacturers and Franchisees

The pain points of the PET injection molding industry have long been well-known to insiders. Especially in high-end sectors like food packaging and medical supplies, excessive acetaldehyde levels, uneven melting, and prolonged production cycles are often the main reasons enterprises lose orders and face penalties. According to industry observations, traditional injection molding machines use an integrated plasticization and injection design, resulting in discontinuous plasticization. This not only leads to short melting times and poor uniformity of the PET melt, but also tends to cause excessive acetaldehyde formation. Many manufacturers consequently face risks of product returns, recalls, and even regulatory penalties—and this also leaves franchisees of traditional injection molding machines stuck in an awkward spot: dealing with cumbersome after-sales service and customer attrition.

Core Advantage: Decoupled Process Targets Pain Points Directly

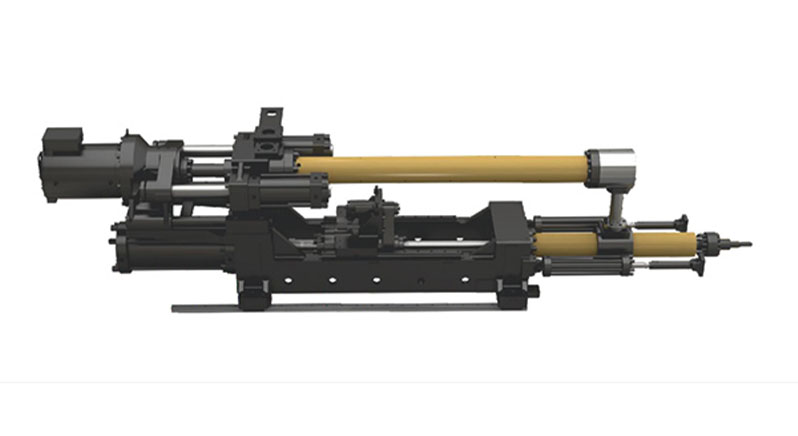

The core advantages of this independent twin-screw injection system directly address these industry pain points. It consists of a dedicated plasticizing screw and an independent injection screw, each performing its own function with complete separation: the plasticizing screw focuses on feeding, compressing, melting, and degassing PET materials, while the injection screw handles melt metering, accumulation, and injection. This decoupled process enables continuous plasticization throughout the entire production cycle.

Practical Value: Quality, Capacity, and Efficiency Improved

In practical use, continuous plasticization not only extends melting time and improves uniformity—effectively controlling acetaldehyde formation and significantly enhancing product quality—but also substantially increases production capacity. Additionally, its parallel operation design allows for plasticization of the next injection while the mold cools. Compared to traditional machines, this parallel workflow significantly reduces the time spent on injection and pressure-holding phases, shortens the overall production cycle, and improves efficiency. These advantages are not overstated—they are based on practical optimizations tailored to PET material properties and injection molding processes, fully complying with industry standards, production needs, and advertising regulations, with no extreme or absolute language used.

For Franchisees: Tangible Profit Potential and Less Burden

For franchisees, the advantages of this system translate into tangible profit potential. First, the product excels at solving industry pain points and has high customer acceptance—manufacturers looking to reduce acetaldehyde levels, improve product quality, shorten cycles, or increase capacity will all actively seek out such targeted equipment, greatly reducing the difficulty of promotion for franchisees. Second, the product offers high stability: process optimizations reduce equipment failures and product defects, significantly easing the after-sales burden on franchisees. They no longer need to invest a lot of energy in handling customer complaints and can focus more on market expansion. Third, the PET injection molding market is growing steadily, with particularly strong demand in the high-end segment. The system’s differentiated advantages allow franchisees to break free from vicious price competition and capture market share in the niche segment.

Third-Party Evaluation: A Pragmatic Choice Worth Considering

From an objective third-party editor’s perspective, the core competitiveness of this independent twin-screw injection system lies in its pragmatic product philosophy—focusing on solving industry pain points through process optimization rather than chasing superficial gimmicks. This philosophy also helps it gain a unique edge in the highly homogeneous injection molding machine market. For franchisees looking to enter the PET injection molding equipment space, choosing a product that truly meets customer needs and has differentiated advantages is far more promising than distributing homogeneous traditional equipment. Undoubtedly, this twin-screw injection system is a choice worth considering in depth.