Alaa, a friend from Egypt, is a CEO of a plastic lotion pump factory. He has factories in Egypt and Saudi Arabia respectively. He comes from an engineering background and has a strong business acumen. This time he came to visit the factory of Lisong injection molding machine. I mainly want to see the operation process of thin-walled meal boxes and IML machines.

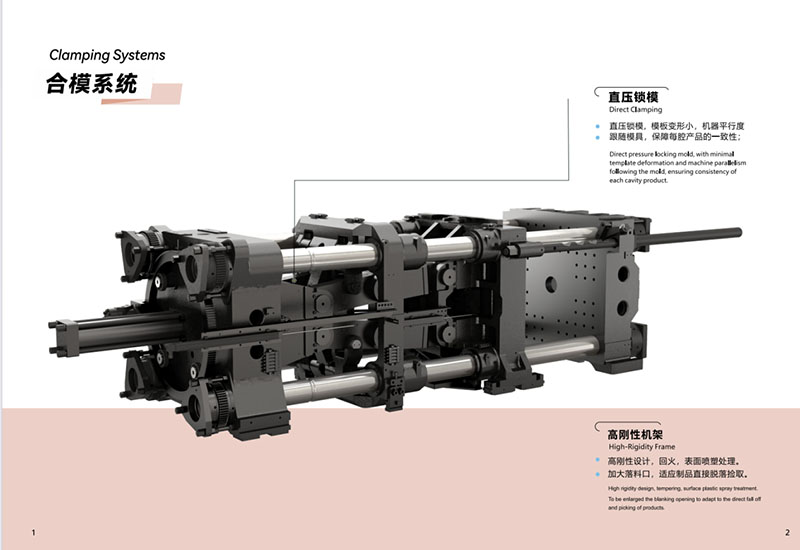

Firstly, he arrived at Lisong's assembly workshop and saw many injection molding machines. Including the thin-walled packaging machine being debugged, the PET preform machine, the bucket specific machine, and the 900 ton two plate machine. Seeing so many machines, he was shocked and speechless. For the unique mold closing and locking structure, he stated that the structure of the force loosening mold closing and locking is completely unique compared to other machines.

The direct pressing locking technology reduces the deformation of the template, and the parallelism of the machine follows the mold, ensuring the consistency of each cavity product. And it can better protect precision molds from damage. Alaa believes that our boss is a very engineer minded person and very intelligent.

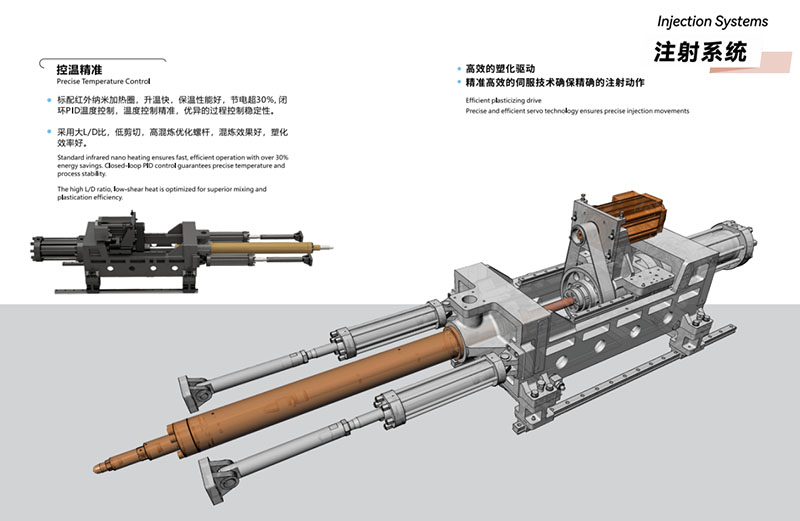

Once again, he saw the unique injection structure of the Lisong injection molding machine, equipped with infrared nano heating coils as standard, which heats up quickly, has good insulation performance, saves more than 30% electricity, closed-loop PID temperature control, precise temperature control, and excellent process control stability. Efficient plasticizing drive and precise servo technology ensure precise injection actions and systems, ensuring stable and precise products in each chamber. Adopting a large L/D ratio, low shear, and high mixing optimization screw, the mixing effect is good and the plasticization efficiency is good.

Alaa said that seeing many of our machines on social media before feels different now when she sees them with her own eyes. Because he witnessed our excellent quality with his own eyes, he wants to establish a long-term cooperation with us. From buying machines to helping us open up the Egyptian market, and ultimately becoming a high-quality manufacturer.